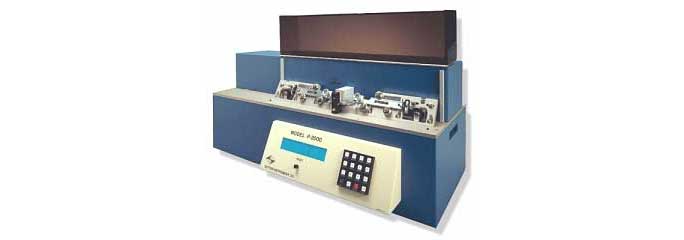

P-2000

The P-2000 micropipette puller represents a significant advance in the technology of fabrication of micropipettes, optical fiber probes, and nanospray tips. The P-2000 integrates a CO2 laser-based heat source with the technology derived from our extensive experience with conventional pullers. This system offers capabilities unmatched by other pullers.

While the P-2000 is suitable for working with most conventional glasses, its primary advantage is the ability to work with quartz (fused silica) glass. Quartz offers superior material properties for a variety of research applications. Quartz is stronger than other glasses and can facilitate penetration through tough tissues which would normally break conventional pipettes1. For applications requiring a low noise glass, users will find that quartz is the lowest noise glass available2,4. Quartz contains none of the metals used in conventional glasses3. Optically, quartz is virtually free from fluorescence when illuminated.

A CO2 laser was selected as the heat source for the P-2000 for several reasons.

- The nominal emission wavelength of the laser approximates the resonant frequency of the SiO2 lattice in glass. Thus quartz and other conventional glasses can be melted when appropriate laser power is supplied.

- Laser heat is clean and leaves no metal residue on the pipette as do conventional heating filaments.

- Laser heat can be turned off instantly, leaving no residual filament heat.

- The user can program the amount of heat (power) supplied to the glass and can determine the distribution of heat along the length of the glass. These factors allow for control of the geometry of the pipette taper.

The P-2000 can store up to 100 separate programs, with each program consisting of up to 8 command lines. Programmable parameters include heat, pull strength, velocity (criterion for the trip point) filament type, and delay (time between the trip point and the hard pull).

One important consideration for the use of the P-2000 is the diameter of the glass used. The optical design produces even heating on glass up to 1.2 mm in outside diameter. Larger diameter glasses can be used with the P-2000 (up to 1.5 mm quartz and 1.8 mm conventional glasses), but the performance is best with glass that is 1.2 mm diameter or less.

The P-2000 works well with small diameter glasses such as HPLC tubing and optical fibers. These smaller diameter glass configurations (0.125 mm > outside diameter < 0.6 mm ) require the installation of some modified components including special glass clamping bars.

These modified components will be installed, if requested, at the time of purchase. As with larger diameter glass, a wide range of tip sizes and taper geometries can be produced with this modified P-2000 and small diameter glass. We have drawn optical fiber tips ranging from less than 10 nm to more than 0.5 nm. Please consult our technical staff for further information.

Features

- Capable of pulling quartz, borosilicate and aluminosilicate glass.

- Fully programmable-including heating filament characteristics.

- The laser has no melting point limit as with conventional metal filaments and therefore cannot be burned out.

- Pulls electrodes with tip diameters that are less than 0.03 µm.

- Optimized velocity sensing circuit for maximized sensitivity and reproducibility.*

- The laser is completely contained, ensuring the safety of the operator.

- Operating life of the CO2 laser is expected to be in excess of ten years with normal use, after which the laser can be refurbished for a nominal charge

- Individual programs can be write protected in order to secure them from inadvertent changes.

- The total time that the heat is on during the pull is displayed for improved program development and troubleshooting.

- A date and time stamp is displayed to show the last time that a program has been changed.

- Preprogrammed sample programs for intracellular and patch pipettes.

Special programming on request

Specifications

Dimensions 94 cm × 48 cm × 48 cm

Weight 43 kg

Electrical 115/230 V, 50/60 Hz

References

- Munoz, J.L. and Coles, J. Quartz micropipettes for intracellular voltage microelectrodes and ion selective microelectrodes. Journal of Neuroscience Methods: 22:57-64, 1987.

- Rae, J.L. and Levis, R. A. A method for exceptionally low noise single channel recordings. European Journal of Physiology - Pflügers Archiv: 420:618-620, 1992.

- Zuazaga, C. and Steinacker, A. Patch-clamp recording of ion channels: Interfering effects of patch pipette glass. News in Physiological Science: 5:155- 159, 1990.

- Levis, R. A. and Rae, J. L. The use of quartz patch pipettes for low noise single channel recording. Biophysical Journal: 65:1666-1677, 1993.

*Patent No.4,600,424

Also See:

Accessories

for all Sutter Instrument

Micropipette Pullers